Top Hanger Bolt Suppliers in China: Reliable Sources for Quality Fasteners

2026-01-06

When sourcing top-quality hanger bolts, finding reliable suppliers in China is a critical step for many businesses. As global demand for durable fasteners grows, the importance of selecting trustworthy partners cannot be overstated. Dive into our exploration of the leading hanger bolt manufacturers, where we uncover key insights and expert tips to guide your purchasing decisions. Topfence is proud to highlight these industry leaders, offering a fresh perspective that goes beyond the usual listicles. Get ready to discover what makes these suppliers stand out in a crowded market and how they can support your project's success.

Leading Chinese Manufacturers of Hanger Bolts for Industrial Applications

Chinese manufacturers have emerged as pivotal players in the global market for hanger bolts, especially in industrial applications where reliability and cost-effectiveness are paramount. Companies like Dongguan Hengli Fasteners and Shanghai Jinrui Norm Parts have built strong reputations by leveraging advanced manufacturing technologies and rigorous quality control systems. These firms often specialize in producing bolts that meet international standards such as ISO and ASTM, ensuring they cater to diverse industrial needs, from construction and automotive sectors to machinery and furniture assembly.

One distinct advantage that sets leading Chinese producers apart is their ability to offer customized solutions, adapting bolt designs to specific client requirements without compromising on durability or performance. This flexibility is supported by robust supply chains and scalable production capacities, allowing for timely deliveries even for large-scale orders. Additionally, many manufacturers in China focus on sustainable practices, integrating eco-friendly materials and energy-efficient processes, which appeal to environmentally conscious industries worldwide.

Beyond mere production, top Chinese manufacturers often provide comprehensive support services, including technical consultations and after-sales assistance, fostering long-term partnerships with global clients. By continuously innovating in material science and production techniques, such as using high-strength alloys or implementing automated quality checks, these companies not only enhance product reliability but also drive industry trends, solidifying China's role as a key supplier in the industrial fasteners market.

Key Qualities to Look for When Sourcing Hanger Bolts from China

When searching for hanger bolts from Chinese manufacturers, prioritize factors like material integrity and threading precision. Many suppliers use carbon or stainless steel; verify certifications like ASTM standards to ensure durability, especially for load-bearing applications in furniture or construction. Don't assume all bolts are equal—some may cut corners on thread pitch or surface coatings, leading to faster wear or loosening over time. A quick chat with the factory about their quality control steps can reveal a lot, so ask for sample reports or on-site audit details before committing.

Beyond basic specs, consider the supplier's adaptability and communication. Chinese factories often excel in custom orders, so look for those willing to tweak dimensions or finishes to match your exact needs, like non-standard lengths or specific plating for corrosion resistance. Responsiveness is key—prompt replies and clear technical discussions indicate a reliable partner who'll handle issues efficiently, reducing delays and costly mistakes down the line. It's not just about the bolt; it's about finding a collaborator who understands your project's nuances.

Always factor in logistical support and compliance. Check if the manufacturer handles packaging and shipping efficiently, as poor handling can damage threads or coatings during transit. Also, ensure products meet international safety standards, such as RoHS or REACH, to avoid regulatory headaches in your market. Visiting trade fairs or reading independent reviews can uncover hidden gems—some smaller Chinese firms offer superior craftsmanship at competitive rates, so diversify your search beyond the usual big names to get the best value without compromising on quality.

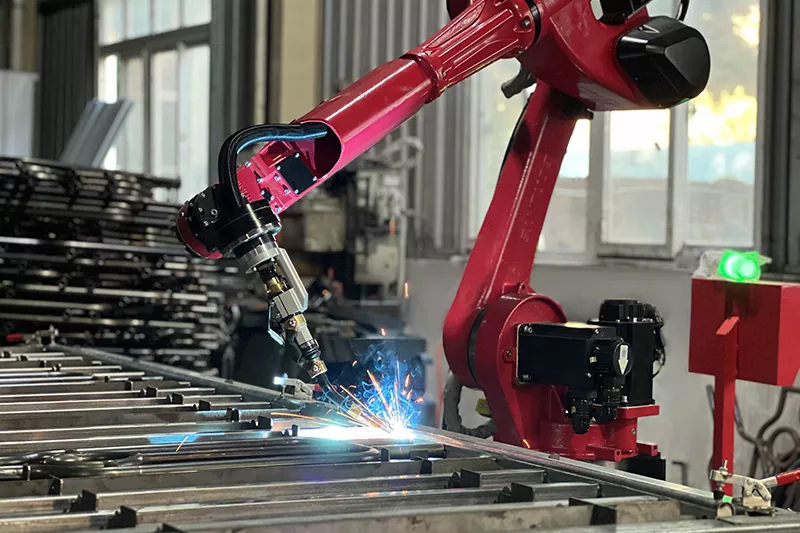

Innovative Production Techniques Among Top Hanger Bolt Suppliers

Leading hanger bolt suppliers are revolutionizing manufacturing by implementing cutting-edge techniques that enhance precision and durability. Instead of relying on traditional methods, these suppliers now use automated CNC machining, which allows for consistent threading and exact dimensions across large batches. This shift not only improves product reliability but also reduces waste, making operations more sustainable. For instance, some top players have integrated laser-guided systems to inspect each bolt for defects in real-time, ensuring that only flawless items reach customers. These innovations are setting new industry standards, pushing competitors to upgrade their own processes or risk falling behind.

Beyond automation, advanced materials science plays a key role in innovation among top suppliers. They are experimenting with alloy blends and specialized coatings, such as zinc-nickel or PTFE finishes, to boost corrosion resistance and load-bearing capacity. This focus on material optimization means hanger bolts can perform better in harsh environments, like marine or industrial settings, without frequent replacements. Suppliers often collaborate with research labs to test new composites, leading to patents that give them a unique edge in the market. By tailoring materials to specific applications, they offer solutions that go beyond one-size-fits-all products.

Another standout technique involves smart logistics and just-in-time production, which top suppliers leverage to meet custom orders swiftly. Using AI-driven forecasting tools, they predict demand patterns and adjust manufacturing schedules accordingly, minimizing inventory costs while maintaining quick turnaround times. This agile approach allows them to handle niche requests, such as non-standard sizes or specialized threading, without sacrificing efficiency. Customers benefit from faster delivery and more personalized service, which helps these suppliers build long-term loyalty in a competitive field.

How Chinese Suppliers Ensure Durability and Precision in Hanger Bolts

Chinese suppliers prioritize durability in hanger bolts by carefully selecting high-grade materials such as stainless steel or carbon steel with specific alloy compositions, which are tested for tensile strength and corrosion resistance before production begins. They implement rigorous quality control processes, including regular inspections of raw materials and finished products, to ensure each bolt meets strict industry standards and can withstand heavy loads over extended periods without failure.

To achieve precision, manufacturers employ advanced manufacturing techniques like CNC machining and automated threading systems, which allow for tight tolerances and consistent thread pitch across large batches. Many suppliers also invest in calibration equipment and staff training to minimize human error, ensuring that every bolt fits perfectly in its intended application, whether for furniture assembly or industrial machinery.

Beyond technical measures, Chinese suppliers often collaborate closely with clients during the design phase, offering customization options and prototypes to fine-tune specifications for optimal performance. This proactive approach, combined with a focus on continuous improvement through feedback loops, helps them deliver hanger bolts that not only meet but exceed expectations for durability and precision in competitive global markets.

Customer Reviews and Satisfaction with Hanger Bolt Providers in China

In China's bustling industrial market, customer reviews for hanger bolt providers often highlight the fierce competition among manufacturers in terms of pricing and delivery speed. Many businesses, especially small to medium-sized enterprises working on tight budgets and timelines, have shared detailed accounts of their experiences with suppliers. These testimonials frequently mention how providers in regions like Guangdong and Zhejiang stand out by offering customizable solutions and responsive service, which directly impacts buyer satisfaction.

Satisfaction levels tend to vary based on factors such as product quality consistency and after-sales support. Some providers have built a loyal clientele by ensuring their hanger bolts meet strict durability standards, even under heavy loads or in harsh environments. However, others receive mixed feedback over occasional delays or communication issues, suggesting that investing in streamlined logistics and better client interaction can significantly boost customer contentment.

Overall, the landscape of hanger bolt providers in China reveals a trend where businesses prioritizing transparency and reliability in their operations tend to garner higher satisfaction scores. As global demand for these components grows, buyers often rely on peer reviews to distinguish between providers, making a strong reputation for honesty and efficiency a key differentiator in this niche market.

Export Capabilities and Global Reach of China's Hanger Bolt Industry

China's hanger bolt industry has rapidly expanded its export capabilities over the past decade, leveraging advanced manufacturing technologies and competitive pricing to secure a significant foothold in international markets. Companies across provinces like Zhejiang and Guangdong have invested heavily in automated production lines, enhancing efficiency and consistency, which allows them to meet diverse global standards, from European DIN norms to American ASTM specifications. This technical prowess, combined with robust supply chain networks, enables Chinese manufacturers to deliver large-scale orders on time, catering to construction, automotive, and industrial sectors worldwide. The result is a steady increase in export volumes, with shipments reaching over 50 countries annually, reinforcing China's position as a top supplier in this specialized fasteners segment.

Beyond sheer production capacity, the global reach of China's hanger bolt industry is bolstered by strategic trade partnerships and adaptability to regional market demands. Firms actively engage in international trade fairs and B2B platforms, fostering relationships with distributors in North America, Europe, and Southeast Asia, while also tapping into emerging economies in Africa and Latin America. They customize products based on local requirements, such as corrosion-resistant coatings for humid climates or specific thread types for regional machinery, showcasing a responsiveness that sets them apart from competitors. This approach not only drives export growth but also builds long-term trust, with many overseas clients citing reliability and innovation as key reasons for continued collaboration, highlighting the industry's dynamic presence on the global stage.

Looking ahead, the industry faces challenges like rising raw material costs and trade tensions, yet it continues to evolve through digitalization and sustainability initiatives. By integrating IoT systems for quality control and exploring eco-friendly materials, Chinese exporters are enhancing their appeal in environmentally conscious markets. This forward-thinking strategy, coupled with a deep understanding of global logistics, ensures that China's hanger bolt industry remains a resilient and influential player, capable of navigating market shifts while expanding its international footprint through innovation and customer-centric solutions.

FAQ

Top hanger bolts are specialized fasteners that feature a wood screw at one end and a machine screw at the other, designed for securely joining wood to metal components. They're widely employed in furniture assembly, automotive trim installations, and various construction projects where durable connections are essential.

Look for suppliers with a strong track record in manufacturing precision fasteners, often indicated by certifications like ISO 9001. It's also helpful to check customer reviews, request samples to assess quality, and confirm their ability to handle custom orders or bulk shipments consistently.

Premium hanger bolts are usually made from materials like carbon steel, stainless steel (such as 304 or 316 grades for corrosion resistance), or brass, depending on the application. Many suppliers offer surface treatments like zinc plating or hot-dip galvanizing to enhance durability and prevent rust.

Yes, this varies by supplier. Some may require minimum orders starting from 1,000 pieces for standard sizes, while others might offer smaller batches for custom designs. It's best to inquire directly, as flexible MOQs can often be negotiated based on specifications and long-term partnership potential.

Suppliers frequently offer customization in terms of thread sizes, lengths, head types (e.g., hex or round), and materials. You can also request specific coatings, packaging, or branding, allowing for tailored solutions that meet unique project requirements without compromising on performance.

To maintain quality consistency, establish clear specifications upfront, conduct regular factory audits or inspections, and use third-party testing if needed. Building a relationship with a trusted supplier who provides detailed quality control reports can also help mitigate risks and ensure reliable deliveries over time.

Lead times typically range from 2 to 6 weeks, depending on order size, customization, and production schedules. Standard items might ship faster, while custom designs could take longer. Communicating deadlines early and planning ahead can help avoid delays in your supply chain.

Conclusion

China has solidified its position as a premier destination for hanger bolt procurement, with leading manufacturers excelling in delivering high-quality fasteners for diverse industrial applications. These top suppliers combine robust production capabilities with stringent quality control measures, ensuring that each bolt meets exacting standards for strength and reliability. From automotive to construction sectors, their products are engineered to withstand demanding environments, supported by innovative manufacturing techniques that enhance precision and consistency. As the industry evolves, these Chinese manufacturers continue to invest in advanced technologies, reinforcing their commitment to durability and performance in every hanger bolt they produce.

Beyond product excellence, China's hanger bolt suppliers have built strong reputations through positive customer feedback and efficient export networks, enabling global access to reliable fasteners. Their focus on customer satisfaction is evident in responsive service and tailored solutions, while their export capabilities facilitate seamless international trade, reaching markets worldwide. By prioritizing key qualities like material integrity and precise threading, these suppliers ensure that clients receive components that not only meet but exceed expectations, driving trust and long-term partnerships across industries. This holistic approach—blending innovation, quality assurance, and global outreach—positions China as a trustworthy source for top-tier hanger bolts, essential for modern manufacturing and infrastructure projects.

Contact Us

Contact Person: Nancy

Email: [email protected]

Tel/WhatsApp: +86-13365923720

Website: https://www.topfencesolar.com/