Advantages and Disadvantages of PVC Knife Coating Tarpaulin

2024-07-31

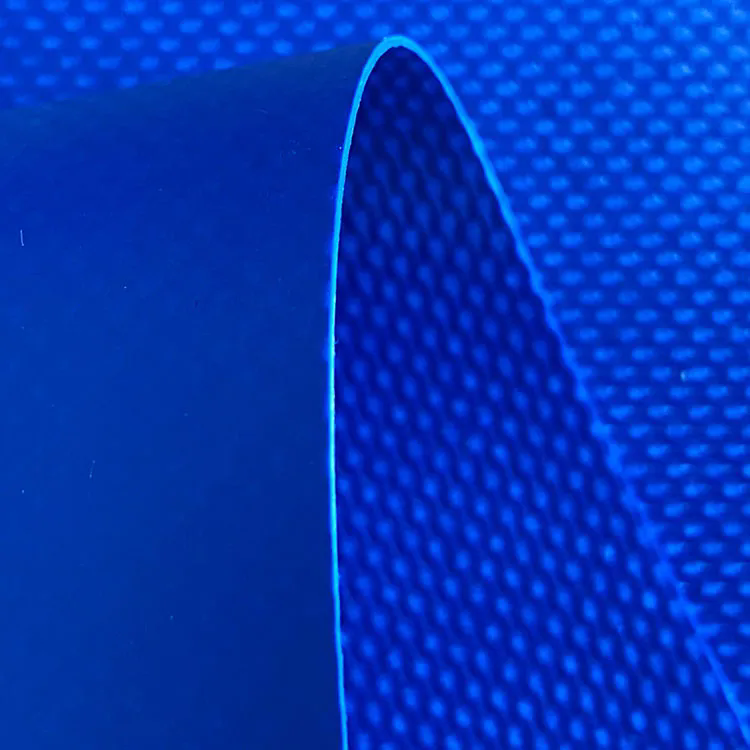

PVC knife coating tarpaulin is a type of tarpaulin that is coated with PVC (polyvinyl chloride) using a specific coating technique known as knife coating. This coating process involves spreading a layer of PVC onto a base fabric to create a durable, waterproof, and flexible material. Here are the key aspects of PVC knife coating tarpaulin:

Key Features

1. Coating Process

- Knife Coating: Involves applying a thin, even layer of PVC to the fabric using a doctor blade (knife). This technique ensures a smooth and uniform coating.

- Multi-Layer Coating: Sometimes, multiple layers of PVC are applied to enhance durability and performance.

2. Materials

- Base Fabric: Typically made from woven polyester or nylon, which provides strength and flexibility. The fabric is coated with PVC to create a robust, waterproof surface.

- PVC Coating: Provides the tarpaulin with resistance to water, chemicals, UV rays, and abrasion.

3. Durability and Strength

- Weather Resistance: PVC-coated tarpaulins are highly resistant to weather conditions, including rain, snow, and UV exposure, making them suitable for outdoor use.

- Tear Resistance: The tarpaulin’s fabric strength combined with the PVC coating enhances tear resistance and overall durability.

4. Applications

- Industrial: Used in manufacturing, construction, and agriculture for covering and protecting materials, machinery, and equipment.

- Transportation: Commonly used as truck covers, container covers, and for tarping loads during transit.

- Outdoor Events: Utilized for tents, banners, and temporary shelters.

- Marine: Suitable for boat covers, tarps, and other maritime applications due to its waterproof properties.

5. Properties

- Waterproof: The PVC coating makes the tarpaulin impermeable to water, keeping contents dry and protected.

- UV Protection: PVC coatings often include UV stabilizers to prevent degradation and discoloration from sun exposure.

- Fire Retardant: Some PVC-coated tarpaulins are treated to be fire retardant, adding an extra layer of safety in certain applications.

- Flexibility: Maintains flexibility and ease of handling even in cold temperatures.

6. Maintenance

- Cleaning: Can be cleaned with water and mild detergent. Avoid harsh chemicals that might damage the PVC coating.

- Storage: Should be stored in a cool, dry place to prevent damage from extreme temperatures or prolonged sunlight exposure.

Advantages

1. High Durability: Provides excellent resistance to physical wear, chemicals, and environmental factors.

2. Versatile Applications: Suitable for a wide range of uses due to its strength and protective qualities.

3. Cost-Effective: Offers a balance between cost and performance, making it an economical choice for many applications.

Disadvantages

1. Environmental Impact: PVC production and disposal can have environmental impacts, including the release of harmful chemicals.

2. Rigidity: PVC tarpaulins can become stiff in extremely cold temperatures, which might affect handling and flexibility.

3. Aesthetic Considerations: The appearance may not be as visually appealing as some other materials, especially if not properly maintained.

Summary

PVC knife coating tarpaulin is a durable and versatile material used in various applications due to its waterproof, UV-resistant, and tear-resistant properties. The knife coating process ensures a uniform and smooth application of PVC, enhancing the material’s overall performance. While offering numerous advantages in terms of durability and protection, considerations such as environmental impact and handling in extreme conditions should be taken into account.