Anatase PVC Titanium Dioxide: A Comprehensive Q&A Guide

2024-10-23

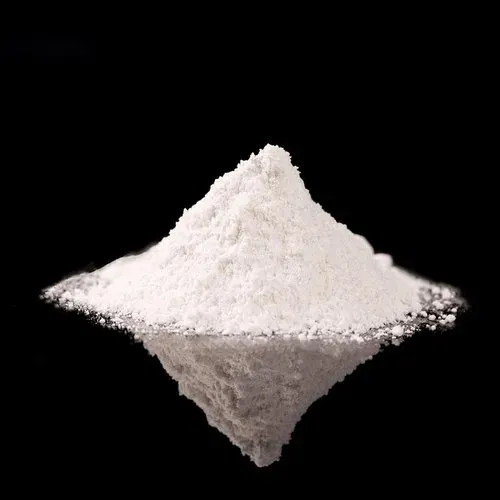

Anatase PVC titanium dioxide is a widely used compound in various industries, particularly in coatings, plastics, and cosmetics. Its exceptional properties make it a preferred choice for enhancing product performance and aesthetic appeal. In this Q&A blog, we delve into the characteristics, applications, and benefits of anatase PVC titanium dioxide.

What Is Anatase PVC Titanium Dioxide?

Anatase PVC titanium dioxide is a form of titanium dioxide (TiO2) with an anatase crystalline structure. It is commonly used as a pigment and filler in polyvinyl chloride (PVC) and other plastic materials. The anatase form of titanium dioxide is known for its superior whiteness, brightness, and opacity, making it an excellent choice for various applications.

What Are the Key Properties of Anatase PVC Titanium Dioxide?

Anatase PVC titanium dioxide possesses several important properties:

High Opacity: It provides excellent coverage, allowing for the effective masking of underlying colors.

Brightness: Anatase TiO2 offers superior whiteness and brightness compared to other pigments.

UV Resistance: It exhibits good resistance to ultraviolet light, which helps protect products from degradation.

Chemical Stability: Anatase PVC titanium dioxide is chemically inert, ensuring it does not react with other materials.

Non-Toxicity: It is considered safe for use in various applications, including cosmetics and food packaging.

What Are the Main Applications of Anatase PVC Titanium Dioxide?

Anatase PVC titanium dioxide is utilized in a variety of industries:

Paints and Coatings: It is widely used in water-based and solvent-based paints to enhance opacity and color stability.

Plastics: In the PVC industry, anatase TiO2 improves the aesthetic quality and durability of plastic products.

Cosmetics: It serves as a pigment in sunscreens, foundations, and other cosmetic products due to its UV protection properties.

Paper: It is added to paper products to improve brightness and opacity.

Inks: Anatase TiO2 enhances the color strength and opacity of printing inks.

How Is Anatase PVC Titanium Dioxide Produced?

Anatase PVC titanium dioxide is produced through various methods, including:

Sulfate Process: Titanium ore is treated with sulfuric acid to produce titanium dioxide, which is then crystallized into the anatase form.

Chloride Process: Titanium tetrachloride is oxidized to produce titanium dioxide, often resulting in a more consistent product.

Precipitation: Various chemical methods can also create anatase TiO2 by precipitating titanium salts.

What Are the Advantages of Using Anatase PVC Titanium Dioxide?

There are several advantages to incorporating anatase PVC titanium dioxide in products:

Enhanced Appearance: It improves the aesthetic qualities of products, providing a bright and attractive finish.

Improved Durability: Its UV resistance contributes to the longevity of coatings and plastics by preventing degradation.

Versatility: Anatase TiO2 can be used in a wide range of applications, making it a valuable additive across various industries.

Cost-Effectiveness: Its ability to enhance product performance often results in lower overall production costs.

How Does Anatase PVC Titanium Dioxide Compare to Rutile Titanium Dioxide?

Anatase and rutile are the two primary crystalline forms of titanium dioxide, each with distinct characteristics:

Opacity: Rutile TiO2 generally offers higher opacity than anatase, making it preferable in certain applications.

Brightness: Anatase has a higher brightness level, which can be advantageous for specific uses.

Durability: Rutile is often considered more durable and resistant to weathering, while anatase may be preferred for applications requiring higher UV protection.

Cost: Anatase is typically less expensive than rutile, making it an attractive option for budget-conscious applications.

What Safety Considerations Are Associated with Anatase PVC Titanium Dioxide?

Anatase PVC titanium dioxide is considered safe for use in many applications. However, it is essential to follow safety guidelines:

Inhalation Risks: Like many fine powders, inhalation of titanium dioxide dust can pose health risks. It is important to use appropriate respiratory protection when handling the powder.

Regulatory Compliance: Ensure that products containing anatase TiO2 meet relevant regulations and safety standards, especially in food and cosmetic applications.

Environmental Impact: While titanium dioxide is non-toxic, it is essential to consider environmental factors during production and disposal.

How Do You Properly Handle and Store Anatase PVC Titanium Dioxide?

To ensure the quality and safety of anatase PVC titanium dioxide:

Storage Conditions: Store in a cool, dry place away from direct sunlight and moisture to prevent clumping or degradation.

Handling Precautions: Use personal protective equipment (PPE), such as gloves and masks, when handling the powder to minimize inhalation and skin contact.

Keep Containers Sealed: Always keep containers tightly closed when not in use to maintain product integrity.

What Future Trends Are Expected in the Use of Anatase PVC Titanium Dioxide?

As industries evolve, several trends may influence the use of anatase PVC titanium dioxide:

Sustainability: There is a growing demand for eco-friendly and sustainable materials, prompting research into greener production methods for TiO2.

Nanotechnology: Advances in nanotechnology may enhance the properties of titanium dioxide, leading to improved performance in coatings and plastics.

Innovative Applications: As the market for specialty coatings and high-performance materials expands, anatase TiO2 may find new applications in various industries.

How Can Manufacturers Choose the Right Type of Titanium Dioxide for Their Products?

When selecting titanium dioxide for a specific application, manufacturers should consider:

Desired Properties: Evaluate whether opacity, brightness, UV resistance, or durability is most critical for the product.

Compatibility: Ensure that the selected form of TiO2 is compatible with the other materials in the formulation.

Cost-Effectiveness: Analyze the cost implications of using different types of titanium dioxide and how it affects overall production budgets.

Regulatory Compliance: Verify that the chosen titanium dioxide meets safety and regulatory standards for its intended use.

Conclusion

Anatase PVC titanium dioxide is a versatile and valuable compound used across various industries for its unique properties and benefits. By enhancing the appearance, durability, and performance of products, anatase TiO2 plays a crucial role in coatings, plastics, cosmetics, and more. Understanding its characteristics and applications can help manufacturers make informed decisions, ensuring quality and compliance in their products. As technology advances, the potential for anatase PVC titanium dioxide continues to grow, paving the way for innovative uses and improvements in product performance.