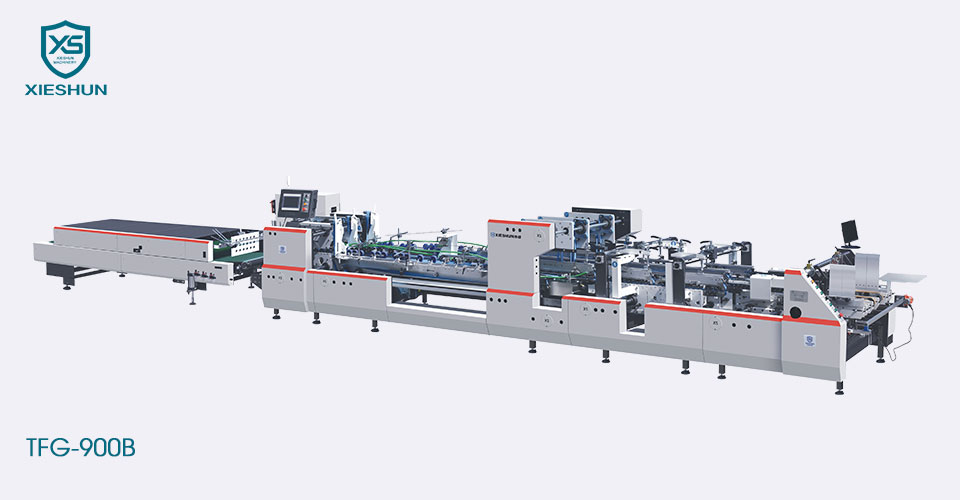

Folder Gluer for Corrugated Boxes: Revolutionizing Packaging Production

2025-05-07

In the ever-evolving world of packaging, efficiency, precision, and reliability are crucial. One of the most important machines in the production of corrugated boxes is the folder gluer. This versatile and essential piece of equipment plays a vital role in the final steps of box production, providing strength, stability, and consistency to corrugated boxes used across a wide range of industries. In this article, we will explore the folder gluer for corrugated boxes, its functions, advantages, and how it has transformed the packaging industry.

What is a Folder Gluer for Corrugated Boxes?

A folder gluer is a specialized machine used in the final stages of corrugated box manufacturing. It is designed to fold and glue the flaps of corrugated cardboard to create a finished box. This equipment ensures that each box is constructed precisely and efficiently, with proper alignment of the flaps for a secure seal.

The machine typically works by feeding flat sheets of corrugated board through various rollers and folding mechanisms. These rollers and folders bend the flaps of the box, while the gluer applies adhesive to the folding edges. Once the glue is applied, the box is pressed into its final shape and can be used for shipping, storage, or retail display.

How Does a Folder Gluer Work?

The process of gluing and folding corrugated boxes with a folder gluer typically involves several key steps:

1. Feeding the Board: Large sheets of corrugated cardboard are fed into the machine, either manually or automatically. These sheets are typically printed with brand logos, barcodes, or other essential information before they are processed by the folder gluer.

2. Folding Mechanism: The machine uses a series of rollers, belts, and folding mechanisms to bend the edges of the corrugated board in preparation for gluing. This is where the flaps of the box are folded into the correct position, ensuring proper alignment for a secure seal.

3. Applying Glue: As the corrugated board moves through the machine, glue is applied to the edges of the flaps. The type of glue used can vary depending on the specific requirements of the product, with most folder gluers utilizing water-based adhesives that offer a strong bond while being eco-friendly.

4. Sealing the Box: Once the glue is applied, the machine presses the glued edges together to form the final box shape. This pressure ensures that the glue bonds securely, resulting in a box that is both durable and ready for use.

5. Cutting and Ejection: After the box is sealed, the folder gluer machine often includes a cutting mechanism that trims the excess cardboard, leaving behind a neat and polished finished product. The completed boxes are then ejected and ready for further packaging or distribution.

Types of Folder Gluers

Folder gluers for corrugated boxes come in several variations to accommodate different production needs. These include:

1. Semi-Automatic Folder Gluers: These machines require manual intervention to load the cardboard sheets and guide them through the process. Semi-automatic folder gluers are often used in smaller-scale production environments where customization and flexibility are needed.

2. Fully Automatic Folder Gluers: These advanced machines are designed to handle large volumes of corrugated boxes with minimal manual input. They automatically feed, fold, glue, and cut the boxes, significantly increasing production speed and efficiency.

3. Rotary Folder Gluers: These machines operate at high speeds and are designed for high-volume production. They utilize rotary systems to apply glue and fold the cardboard, making them ideal for mass production of boxes.

4. Straight-Line Folder Gluers: This type of folder gluer is designed for producing boxes with straight-line folds, typically used in shipping boxes. It’s simpler in design and typically operates at slower speeds than rotary gluers but offers flexibility for various box styles.

Advantages of Using a Folder Gluer for Corrugated Boxes

1. Increased Production Speed

One of the biggest benefits of a folder gluer is the speed at which it can produce corrugated boxes. Whether it’s a semi-automatic or fully automatic machine, folder gluers drastically reduce the time needed to assemble boxes, making them ideal for mass production and high-demand environments. This efficiency translates to increased output and cost savings for manufacturers.

2. Improved Consistency and Quality

The folder gluer ensures that each box is folded and glued with precision, resulting in a high-quality finished product every time. Manual assembly of boxes often leads to inconsistencies in fold alignment and glue application, which can affect the strength and functionality of the box. With a folder gluer, each box is uniformly constructed, leading to higher-quality packaging that better protects products.

3. Customization Options

Folder gluers offer flexibility in the types of corrugated boxes they can produce. From simple rectangular boxes to complex custom designs, the machine can handle various sizes and styles, including regular slotted containers (RSC), die-cut boxes, and more. This customization makes folder gluers ideal for industries that require specialized packaging.

4. Reduced Labor Costs

With the automation of the folding, gluing, and cutting process, folder gluers significantly reduce the need for manual labor. This reduction in labor not only cuts costs but also lowers the risk of human error, improving overall production efficiency and reducing waste.

5. Enhanced Durability and Strength

The folder gluer helps create boxes with better structural integrity, ensuring that products remain safe during transit and storage. The uniform application of glue and the precision of the folding process contribute to the box’s strength, allowing it to hold up under pressure.

6. Eco-Friendly Option

Folder gluers can also be more environmentally friendly than other methods of box assembly. Many modern machines use water-based adhesives that are non-toxic and biodegradable, reducing the environmental impact of packaging production. Additionally, the efficient use of materials and energy in the machine further minimizes waste.

Applications of Folder Gluers for Corrugated Boxes

Folder gluers for corrugated boxes are used in a wide range of industries, including:

E-commerce and Retail: Packaging for shipping products to customers.

Food and Beverage: Boxes for storing and shipping food items.

Electronics and Appliances: Sturdy boxes for shipping electronic products.

Pharmaceuticals and Healthcare: Safe packaging for medical products and devices.

Industrial Goods: Heavy-duty boxes for shipping machinery and equipment.

Conclusion

The folder gluer has revolutionized the production of corrugated boxes by providing a reliable, efficient, and cost-effective solution for packaging needs. With the ability to produce high-quality boxes at impressive speeds, folder gluers have become an essential tool for manufacturers worldwide. Whether you’re producing simple shipping boxes or customized packaging solutions, investing in a folder gluer will improve your packaging processes, enhance the durability of your boxes, and ultimately boost your business’s bottom line.