Key aspects related to bucket teeth forgings

2024-03-07

Bucket teeth forgings refer to the process of manufacturing the teeth used on excavation buckets for heavy machinery, such as excavators, loaders, and backhoes. These teeth are crucial components in construction, mining, and earthmoving equipment, as they directly engage with the ground to scoop and lift materials. Forgings are often preferred for bucket teeth due to their ability to provide strength, durability, and resistance to wear. Here are some key aspects related to bucket teeth forgings:

1. Forging Process:

- Open Die Forging: In open die forging, the heated metal is shaped by repeated hammering or pressing between flat or shaped dies. This process is suitable for creating the rough shape of the bucket tooth.

- Closed Die Forging: Closed die forging, or impression die forging, involves shaping the metal within dies with a precut profile of the desired bucket tooth. This method is useful for achieving more complex shapes and precise dimensions.

2. Material Selection:

- Common materials for bucket teeth forgings include alloy steels or wear-resistant steels that can withstand the abrasive conditions encountered during excavation. The choice of material depends on factors such as hardness, toughness, and wear resistance.

3. Heat Treatment:

- After the forging process, bucket teeth may undergo heat treatment to enhance their mechanical properties. Heat treatment processes like quenching and tempering are often employed to achieve the desired hardness and toughness.

4. Machining and Finishing:

- Following the forging and heat treatment processes, bucket teeth may undergo machining operations to achieve precise dimensions and improve the surface finish. Machining may involve processes such as milling, grinding, or drilling.

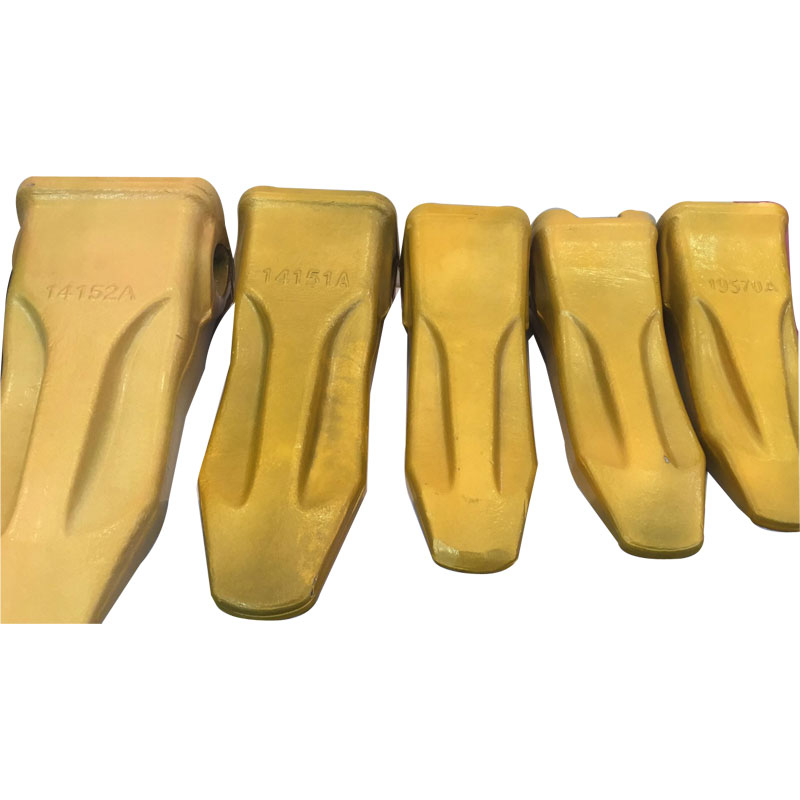

5. Types of Bucket Teeth:

- There are various types of bucket teeth designed for specific applications, including standard, long, and rock penetration teeth. The choice of bucket teeth depends on the nature of the material being excavated and the desired performance characteristics.

6. Wear Resistance:

- Bucket teeth forgings are designed to resist wear, abrasion, and impact, ensuring a longer lifespan and improved performance in challenging excavation conditions.

The manufacturing of bucket teeth forgings requires careful consideration of material properties, forging processes, and heat treatment methods to ensure the final product meets the performance and durability requirements for heavy-duty excavation equipment. These forged bucket teeth play a crucial role in the efficiency and productivity of construction and mining operations.