Laminated Steel Film for Making Cans: The Key to Durability and Innovation in Packaging

2024-08-22

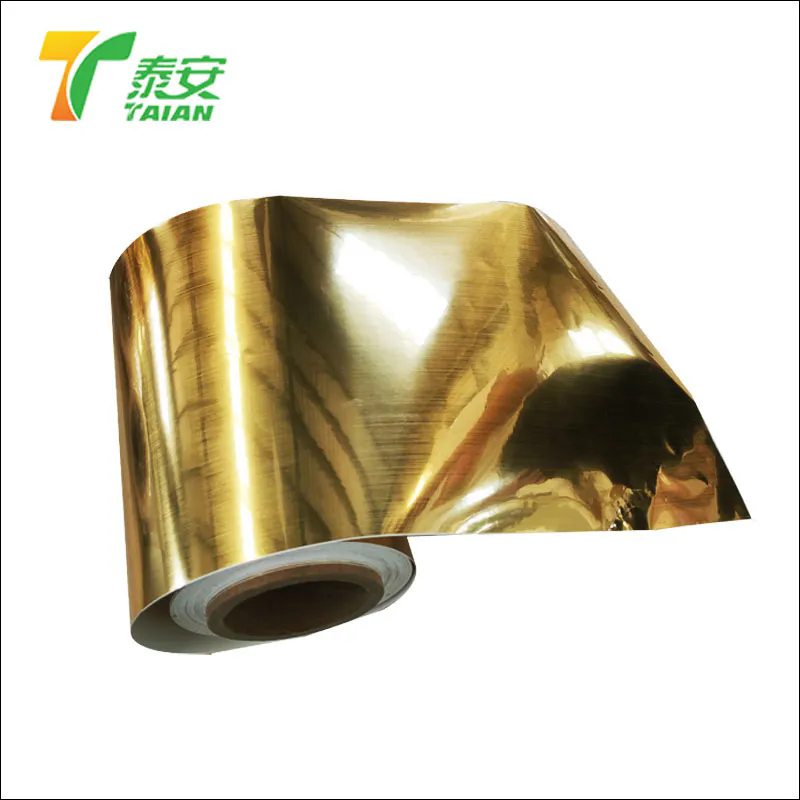

In the realm of packaging, particularly in the food and beverage industry, the materials used play a crucial role in ensuring product quality, safety, and longevity. Laminated steel film is a standout material in this regard, widely used in the production of cans. This innovative material combines the strength of steel with the protective properties of film, creating a packaging solution that is both durable and efficient. In this blog, we will explore the features, benefits, and applications of laminated steel film, highlighting its significance in modern can manufacturing.

What Is Laminated Steel Film?

Laminated steel film is a multi-layer material used in the production of cans and other packaging. It consists of a steel base coated with one or more layers of film, typically made from polymers such as polyester or polypropylene. The lamination process involves bonding these layers together to enhance the properties of the steel and create a composite material with superior performance characteristics.

Features of Laminated Steel Film

1. Multi-Layer Construction:

Laminated steel film features a multi-layer structure that combines steel with polymer films. This construction provides a balance of strength, flexibility, and protection.

2. Corrosion Resistance:

The polymer layers protect the steel from corrosion and rust, ensuring that the cans maintain their integrity even in challenging environments. This is particularly important for cans that will be exposed to moisture or acidic contents.

3. Barrier Properties:

The film layers provide excellent barrier properties, preventing the ingress of moisture, gases, and light. This helps to preserve the freshness and quality of the contents, extending shelf life.

4. Printability:

Laminated steel film offers a smooth surface that is ideal for printing. This allows for high-quality graphics and branding on cans, enhancing product visibility and appeal.

5. Strength and Durability:

The steel core provides structural strength and durability, making laminated steel film suitable for a wide range of applications, including food and beverage cans, aerosol cans, and more.

6. Flexibility:

The polymer layers add flexibility to the material, allowing for the production of cans with various shapes and sizes. This flexibility also aids in the canning process, including forming, filling, and sealing.

Benefits of Laminated Steel Film

1. Enhanced Protection:

Laminated steel film offers superior protection against external factors such as moisture, light, and oxygen. This helps to maintain the quality and safety of the contents, reducing the risk of spoilage and contamination.

2. Extended Shelf Life:

The barrier properties of laminated steel film contribute to the extended shelf life of products. By preventing the entry of external elements, the film helps to keep contents fresh and preserved for longer periods.

3. Improved Product Integrity:

The strength of the steel core ensures that cans maintain their structural integrity, even under pressure or impact. This reduces the likelihood of can deformation or rupture during handling and transportation.

4. Versatile Applications:

Laminated steel film is suitable for a wide range of applications, from food and beverage cans to aerosol containers and industrial packaging. Its versatility makes it a valuable material in various industries.

5. Aesthetic Appeal:

The smooth surface of laminated steel film allows for high-quality printing and labeling. This enhances the visual appeal of cans and supports effective branding and marketing efforts.

6. Cost-Effective:

While laminated steel film may have a higher initial cost compared to some other packaging materials, its durability and protective properties can lead to cost savings in the long run by reducing product spoilage and extending shelf life.

Applications of Laminated Steel Film

1. Food and Beverage Cans:

Laminated steel film is widely used in the production of cans for food and beverages. It helps to preserve the flavor, freshness, and safety of products such as canned vegetables, soups, and soft drinks.

2. Aerosol Cans:

The material is also used in aerosol cans, where its strength and corrosion resistance are essential for containing pressurized substances. Laminated steel film ensures the safe and effective delivery of products like sprays and cleaners.

3. Industrial Packaging:

In addition to consumer products, laminated steel film is used for industrial packaging applications. Its durability and barrier properties make it suitable for packaging chemicals, paints, and other industrial goods.

4. Personal Care Products:

Laminated steel film is utilized in the packaging of personal care products, including sprays and lotions. The film helps to maintain product integrity and extends shelf life.

5. Pharmaceuticals:

The material is also used in pharmaceutical packaging, where it provides protection against moisture and light, ensuring the stability and efficacy of medications.

Tips for Using Laminated Steel Film

1. Select the Right Film Thickness:

Choose a film thickness that matches the requirements of your application. Thicker films may offer additional protection but can also impact cost and flexibility.

2. Ensure Proper Laminating Process:

Work with experienced manufacturers to ensure that the lamination process is performed correctly. Proper bonding of the steel and film layers is crucial for optimal performance.

3. Consider Printing Requirements:

If you plan to print on the cans, ensure that the laminated steel film is compatible with your printing methods. High-quality printing enhances branding and product appeal.

4. Monitor Storage Conditions:

Store laminated steel film in a dry, cool environment to prevent damage to the material before use. Proper storage helps maintain the quality and performance of the film.

5. Adhere to Regulations:

Ensure that the laminated steel film complies with relevant industry regulations and standards, particularly for food and pharmaceutical applications. Compliance ensures safety and quality.

Conclusion

Laminated steel film represents a significant advancement in packaging technology, combining the durability of steel with the protective properties of film. Its versatility, strength, and barrier capabilities make it an excellent choice for a wide range of applications, from food and beverage cans to aerosol and industrial packaging. By understanding the features and benefits of laminated steel film, manufacturers and designers can make informed decisions and leverage this innovative material to enhance product quality, safety, and market appeal. Embrace the advantages of laminated steel film and elevate your packaging solutions to new heights.