Overview of Aluminum Electrophoresis

2024-06-27

Aluminum electrophoresis refers to a process involving the use of aluminum in electrophoretic deposition (EPD). This technique utilizes an electric field to deposit charged particles (in this case, aluminum ions or particles) onto a conductive surface, typically a metal substrate or a material coated with a conductive layer.

Here's an overview of aluminum electrophoresis:

1. Principle: Electrophoretic deposition is based on the principle that charged particles in a suspension migrate towards an oppositely charged electrode under the influence of an electric field. In aluminum electrophoresis, aluminum ions or particles are dispersed in a liquid medium (often an aqueous solution or solvent-based suspension).

2. Process:

- Preparation of Suspension: The aluminum particles or ions are dispersed in a suitable liquid medium along with stabilizers and additives to control deposition characteristics.

- Substrate Preparation: The substrate (often metal or a material with a conductive coating) is cleaned and prepared to ensure good adhesion.

- Electrophoretic Deposition: The substrate and a counter-electrode are immersed in the suspension. When an electric current is applied, aluminum particles migrate towards the substrate, depositing a uniform coating due to their charge and the electric field.

- Rinse and Cure: After deposition, the coated substrate is typically rinsed to remove excess suspension and then cured to solidify the coating, often through drying or baking processes.

3. Applications:

- Corrosion Protection: Aluminum electrophoretic coatings are used to provide corrosion resistance to metal substrates, improving their durability and longevity.

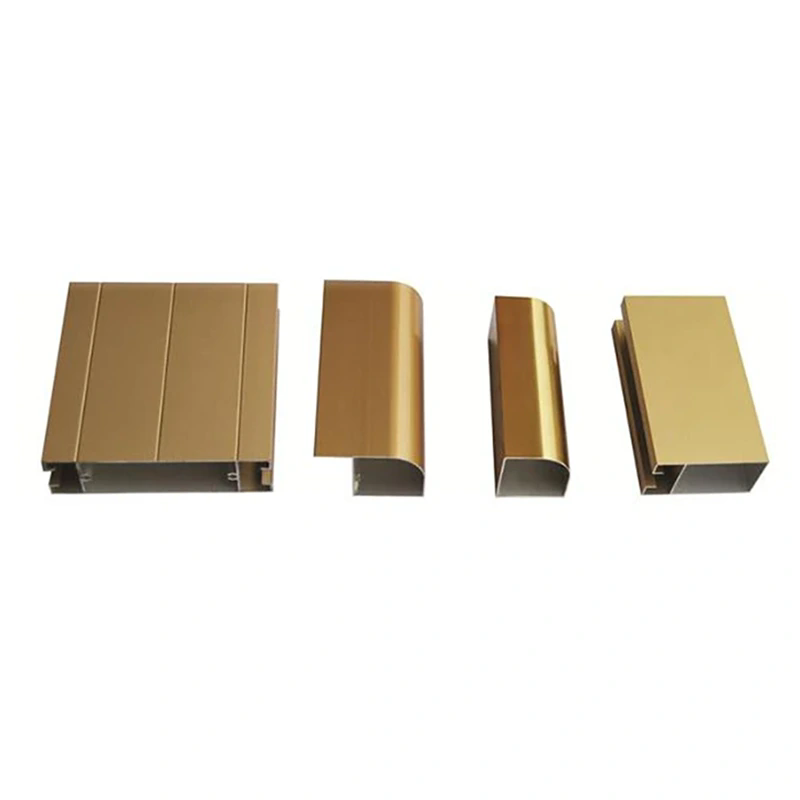

- Decorative Finishes: These coatings can also be applied for aesthetic purposes, providing a smooth, even, and decorative surface finish.

- Functional Coatings: In some applications, aluminum electrophoretic coatings are used for their electrical conductivity or thermal properties.

- Automotive and Aerospace: Common industries where aluminum electrophoresis is applied include automotive parts, aerospace components, and architectural applications.

4. Advantages:

- Uniformity: EPD ensures uniform coating thickness, even on complex shapes and surfaces.

- Efficiency: It is a cost-effective method for applying thin, adherent coatings with minimal material waste.

- Environmentally Friendly: EPD typically uses water-based suspensions, reducing environmental impact compared to solvent-based coatings.

5. Challenges:

- Process Control: Achieving consistent deposition quality requires precise control of suspension composition, electric field parameters, and process conditions.

- Surface Preparation: Proper surface preparation of the substrate is crucial for adhesion and coating performance.

- Equipment and Maintenance: EPD equipment must be maintained to ensure consistent operation and performance.

Overall, aluminum electrophoresis is a versatile coating method that offers significant advantages in terms of coating uniformity, efficiency, and environmental impact, making it a preferred choice in various industrial applications requiring high-performance surface treatments.