PU Tubes: Flexibility, Durability, and Versatility for Diverse Industrial and Medical Applications

2025-04-23

PU (Polyurethane) tubes are widely used in various industries due to their impressive combination of flexibility, durability, and resistance to wear and tear. Polyurethane, as a material, is known for its outstanding mechanical properties and can be processed into a range of products, including tubes and hoses, that serve diverse functions across sectors such as automotive, manufacturing, and medical applications.

One of the primary advantages of PU tubes is their exceptional flexibility. Unlike traditional rubber or plastic tubes, PU tubes can bend and flex without cracking or losing their shape. This flexibility makes them ideal for applications that require movement, such as in automated machinery, robotics, and fluid transfer systems. The ability to maneuver around tight spaces while maintaining structural integrity is crucial in environments where space is limited or equipment is constantly in motion.

The durability of PU tubes is another key feature that sets them apart from other types of tubing. Polyurethane material is highly resistant to abrasion, making PU tubes suitable for harsh conditions where they are exposed to friction and wear. Whether it's a production line where materials are moved frequently or a construction site where the tubing may come into contact with rough surfaces, PU tubes can withstand the stresses of such environments without degrading quickly. This resistance to abrasion also extends the lifespan of the tubes, making them a cost-effective option in the long run.

In addition to abrasion resistance, PU tubes are also highly resistant to chemicals, oils, and fuels, which is another reason they are popular in industries like automotive and manufacturing. When exposed to these substances, PU tubes maintain their shape and functionality, which is vital in systems that deal with corrosive or hazardous materials. This chemical resistance makes PU tubes versatile and reliable, allowing them to be used in applications where other materials might degrade or fail.

Another benefit of PU tubes is their ability to operate effectively over a wide temperature range. Whether it's extreme cold or high temperatures, polyurethane tubes can handle various environmental conditions without becoming brittle or soft. This thermal stability makes PU tubes an ideal choice for industries that experience fluctuating or extreme temperatures, such as refrigeration, automotive, and construction industries.

PU tubes are also lightweight compared to other materials like metal or rubber, which contributes to their ease of handling and installation. Their lightweight nature allows for easy transportation and reduces the overall weight of systems or machinery in which they are used. Additionally, the flexibility and lightness of PU tubes make them easier to cut, shape, and customize according to specific requirements.

One of the most notable features of PU tubes is their excellent resistance to aging and environmental factors such as UV exposure and ozone. Unlike rubber tubes, which can degrade and crack when exposed to sunlight over time, PU tubes retain their strength and elasticity even after prolonged exposure to UV rays and other environmental stresses. This makes them a good choice for outdoor applications where the tubing may be exposed to the elements, ensuring long-lasting performance without the need for frequent replacements.

The versatility of PU tubes also extends to their use in medical and healthcare applications. In these fields, where sterility and precision are essential, PU tubes are used in various devices and equipment, including catheters, feeding tubes, and IV lines. The non-toxic nature of polyurethane makes it a safe option for medical use, and its ability to be produced in a variety of sizes and lengths ensures it meets the specific needs of healthcare professionals.

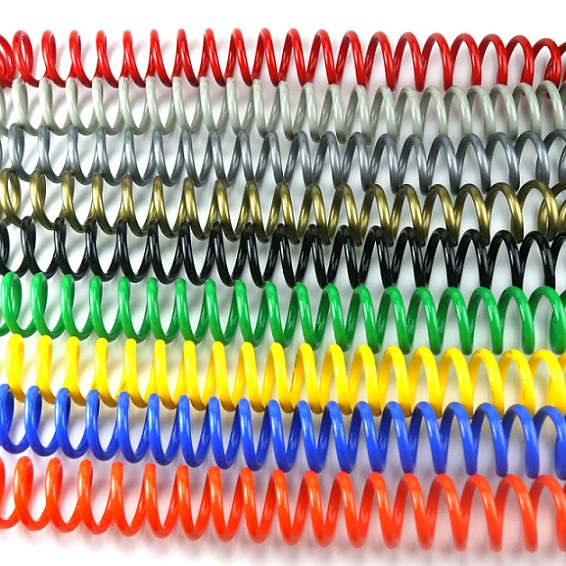

PU tubes are available in various forms, including clear, opaque, and colored options. This allows for easy identification and customization in different industries. Clear tubes, for example, are often used in fluid transfer systems where it's important to visually monitor the flow of liquids or gases. Colored tubes are used for applications that require distinct identification, helping to prevent mix-ups in complex systems.

Due to their many advantages, PU tubes are being increasingly utilized across industries that require materials with high performance and reliability. Whether used in industrial machinery, medical devices, or automotive systems, PU tubes offer a high level of flexibility, durability, and resistance to environmental factors that make them indispensable in today’s manufacturing and technological landscape. As industries continue to innovate and require more advanced materials, PU tubes will likely remain a go-to solution for a wide range of applications.