Thermal Lamination Film: Protecting and Enhancing Printed Materials

2025-06-27

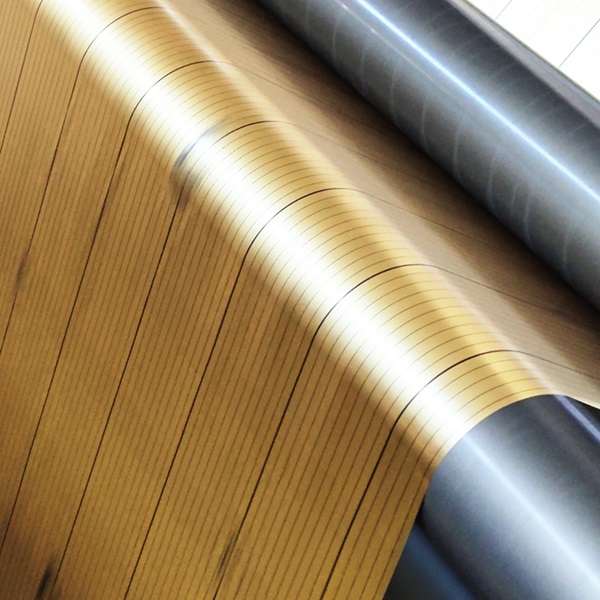

Thermal lamination film is a plastic film used to cover printed materials with a protective layer through a heat-activated adhesive process. When heated in a laminating machine, the film melts the adhesive and bonds securely to the surface, creating a durable, clear, and often glossy or matte finish.

Types of Thermal Lamination Film

Glossy Lamination Film: Provides a shiny, vibrant finish that enhances colors and contrast.

Matte Lamination Film: Offers a non-reflective, smooth finish for a professional, subdued look.

Satin Lamination Film: Combines features of both matte and glossy for a soft sheen.

Textured Films: Add special effects or tactile finishes.

Common Materials Used

Polypropylene (PP): Lightweight and flexible, often used for everyday lamination.

Polyester (PET): Durable and heat-resistant, suitable for heavy-duty applications.

Applications

Business cards, ID cards, and badges

Posters, photographs, and artwork

Menus and brochures

Important documents and certificates

Packaging materials and labels

Benefits of Thermal Lamination Film

Protection: Guards against moisture, dirt, fingerprints, and tearing.

Durability: Extends the life of printed materials by adding strength.

Enhanced Appearance: Improves color vibrancy and surface finish.

Ease of Use: Quick lamination with standard heat-based machines.

Cost-Effective: Affordable way to upgrade and preserve printed products.

Conclusion

Thermal lamination film is an effective solution for protecting and enhancing printed materials, offering a balance of durability and aesthetic appeal. Whether for everyday office use or professional printing needs, thermal lamination adds value and longevity to your documents and designs.