Understanding Arm Cylinder Cushioned: The Benefits and Applications

2024-10-09

When it comes to industrial automation and machinery, hydraulic and pneumatic systems play a crucial role in ensuring smooth and efficient operations. One of the essential components in these systems is the cushioned arm cylinder. This blog will explore what arm cylinder cushioned systems are, their benefits, applications, and tips for selecting the right one for your needs.

What is an Arm Cylinder Cushioned?

An arm cylinder cushioned is a type of actuator that provides linear motion, often used in various industrial applications. These cylinders use hydraulic or pneumatic pressure to extend and retract a piston rod, converting fluid power into mechanical force. The "cushioned" aspect refers to the built-in cushioning mechanism that helps to absorb shocks and reduce noise during operation, providing smoother motion and minimizing wear and tear on the equipment.

Key Components of Arm Cylinder Cushioned

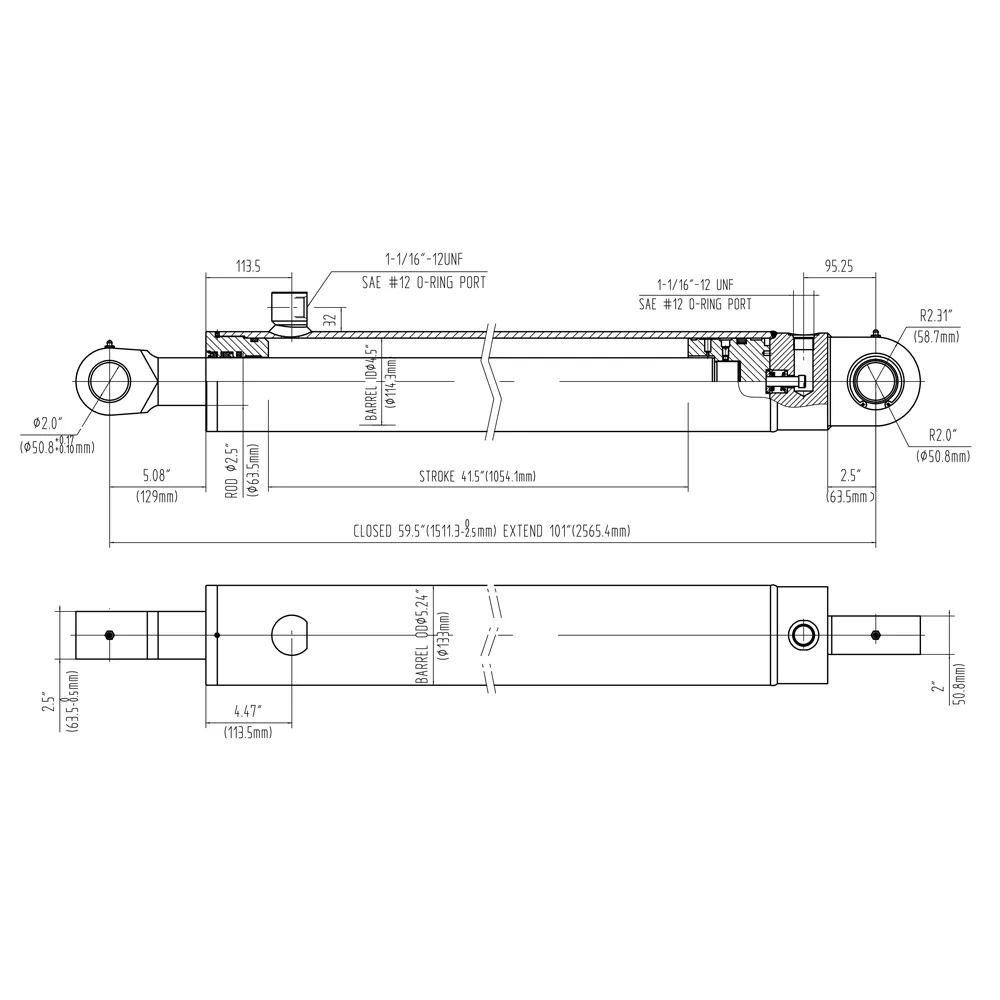

1. Cylinder Body: The main housing that contains the piston and other internal components.

2. Piston: The moving part within the cylinder that creates the linear motion when pressure is applied.

3. Rod: The component connected to the piston that extends and retracts outside the cylinder.

4. Cushioning Mechanism: A feature designed to slow down the piston as it approaches the end of its stroke, reducing impact and noise.

5. Ports: Openings for fluid entry and exit, allowing the cylinder to be connected to a hydraulic or pneumatic system.

Benefits of Arm Cylinder Cushioned

1. Reduced Shock and Vibration

One of the primary benefits of cushioned arm cylinders is their ability to absorb shocks and vibrations during operation. This cushioning effect leads to smoother operation and significantly reduces the risk of damage to the cylinder and connected components.

2. Extended Lifespan

By minimizing the impact forces during operation, cushioned cylinders tend to have a longer lifespan than standard cylinders. This durability reduces the frequency of replacements and maintenance, ultimately saving costs for businesses.

3. Improved Precision

Cushioned arm cylinders provide better control over the movement of the piston, allowing for more precise positioning. This precision is essential in applications where accuracy is critical, such as in assembly lines and automated machinery.

4. Noise Reduction

The cushioning mechanism helps to dampen noise levels during operation, creating a quieter working environment. This feature is especially important in settings where noise reduction is a priority, such as in manufacturing facilities or laboratories.

5. Versatile Applications

Arm cylinder cushioned systems can be used in various applications across different industries. Their versatility makes them suitable for tasks ranging from material handling to robotics.

Applications of Arm Cylinder Cushioned

1. Manufacturing and Assembly

In manufacturing and assembly lines, cushioned arm cylinders are commonly used for tasks such as lifting, pushing, and positioning components. Their ability to handle heavy loads and provide smooth motion makes them ideal for these environments.

2. Robotics

In robotics, cushioned arm cylinders are employed in robotic arms to achieve precise movements and gentle handling of objects. This precision is vital for tasks such as welding, painting, and assembly.

3. Automotive Industry

Cushioned cylinders are used in automotive applications, such as robotic welding arms, automated assembly lines, and testing equipment. Their ability to provide controlled motion is crucial in ensuring the quality and efficiency of production processes.

4. Packaging and Material Handling

In packaging and material handling systems, cushioned arm cylinders facilitate the movement and placement of products with care. Their smooth operation reduces the risk of damaging fragile items during transit.

5. Food and Beverage Industry

Cushioned arm cylinders are used in food processing and packaging equipment, where gentle handling and precise movement are required. Their ability to reduce noise is also beneficial in maintaining a quiet and efficient working environment.

Choosing the Right Arm Cylinder Cushioned

When selecting an arm cylinder cushioned for your application, consider the following factors:

1. Load Capacity

Determine the load requirements of your application. Ensure that the chosen cylinder can handle the weight and force needed for optimal performance.

2. Stroke Length

Consider the required stroke length based on the application’s movement needs. Ensure that the selected cylinder provides the necessary range of motion.

3. Operating Pressure

Check the operating pressure of your hydraulic or pneumatic system. Choose a cushioned cylinder that can withstand the pressure levels while providing the desired performance.

4. Mounting Options

Examine the available mounting configurations to ensure compatibility with your equipment. Different cylinders may have specific mounting requirements, so it’s essential to choose one that fits your setup.

5. Cushioning Features

Look for specific cushioning features that may enhance performance based on your application needs. Some cylinders may offer adjustable cushioning to fine-tune the operation.

Conclusion

Arm cylinder cushioned systems are invaluable components in modern industrial automation. Their ability to provide smooth, controlled motion while reducing shock and noise makes them ideal for various applications across multiple industries. By understanding the benefits, applications, and selection criteria for cushioned cylinders, businesses can optimize their operations and improve efficiency. Investing in the right arm cylinder cushioned system not only enhances performance but also contributes to the longevity of equipment and reduced operational costs.