Understanding Seal Strips: Essential Components for Sealing and Insulation

2025-05-12

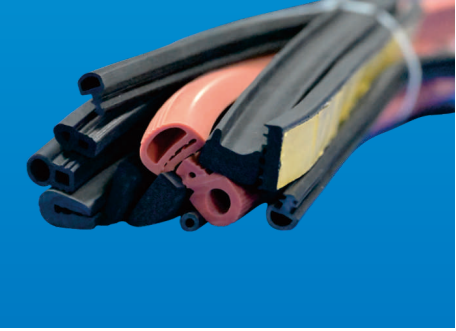

Seal strips, also known as sealing strips or sealing gaskets, are essential components used in a variety of industries and applications. These strips are designed to create tight seals between two surfaces, preventing the infiltration of air, water, dust, and other unwanted elements. Whether in automotive, construction, electronics, or other sectors, seal strips play a vital role in improving product performance, energy efficiency, and durability.

What are Seal Strips?

A seal strip is a flexible material typically made from rubber, silicone, foam, or other elastomers, and it is used to provide a secure seal between two surfaces. Seal strips are available in various shapes, sizes, and materials to cater to specific requirements of different industries. The primary function of a seal strip is to prevent leakage of fluids or gases, insulate against heat or cold, and protect against dust and contaminants.

Types of Seal Strips

There are several types of seal strips, each designed for specific applications. Some of the most common types include:

1. Rubber Seal Strips:

Rubber seal strips are among the most commonly used types. They provide excellent flexibility, durability, and resistance to wear and tear. Rubber seal strips are typically used in automotive applications (e.g., doors and windows), household appliances (e.g., refrigerators), and industrial machinery.

2. Silicone Seal Strips:

Silicone seal strips are highly resistant to extreme temperatures, making them ideal for use in environments with high heat or cold. They are commonly used in applications like ovens, HVAC systems, and automotive parts.

3. Foam Seal Strips:

Foam seal strips are soft and compressible, making them ideal for creating a tight seal in areas that need to absorb shock or vibration. They are used in doors, windows, and air-conditioning systems to reduce noise and provide insulation.

4. Metal Seal Strips:

Metal seal strips are often used in heavy-duty industrial applications. They offer high resistance to wear, pressure, and environmental factors. These strips are used in sealing high-pressure or high-temperature areas, such as in engines or gas pipelines.

5. EPDM Seal Strips:

EPDM (Ethylene Propylene Diene Monomer) seal strips are widely used in automotive and construction applications. Known for their superior resistance to UV radiation, ozone, and weathering, EPDM seal strips are perfect for outdoor applications, including sealing windows, doors, and roofs.

Applications of Seal Strips

Seal strips are used in a wide range of industries and applications, offering solutions for sealing, insulation, and protection. Some common applications include:

1. Automotive Industry:

In the automotive industry, seal strips are used to seal car doors, windows, sunroofs, and trunks. These seals prevent water, dust, and noise from entering the vehicle while also providing thermal insulation. Rubber and EPDM seal strips are particularly popular in automotive sealing applications due to their durability and resistance to harsh weather conditions.

2. Construction and Building:

In construction, seal strips are used to seal doors, windows, and gaps in walls and floors to improve energy efficiency and prevent drafts. Seal strips are also employed in roofing systems to ensure waterproofing and insulation. They are essential in both residential and commercial construction for enhancing comfort and reducing energy costs.

3. Electronics and Appliances:

Many household appliances, including refrigerators, air conditioners, and washing machines, use seal strips to prevent leaks and ensure proper insulation. Silicone and rubber seal strips are ideal for appliances that need to maintain temperature control or moisture resistance. For example, a refrigerator door seal strip keeps cold air inside while preventing warm air from entering.

4. Industrial Machinery:

Seal strips are vital in industrial machinery, where they are used to seal joints, doors, or compartments. In industrial environments, seals help prevent contaminants like dust, dirt, or chemicals from entering sensitive areas. Additionally, they provide insulation against high temperatures, reducing energy losses and protecting internal components.

5. HVAC Systems:

Seal strips are also essential in heating, ventilation, and air conditioning (HVAC) systems. They are used to seal ducts, joints, and components to ensure proper airflow and energy efficiency. A well-sealed HVAC system can significantly reduce energy consumption and improve overall system performance.

Benefits of Seal Strips

The use of seal strips offers several key benefits, including:

1. Improved Insulation:

Seal strips help maintain the internal temperature of buildings and vehicles by preventing the flow of heat and cold. This energy-efficient insulation reduces heating and cooling costs and provides a more comfortable environment.

2. Waterproofing and Leak Prevention:

One of the primary functions of seal strips is to prevent water leakage. They help ensure that windows, doors, and other components remain sealed, preventing water from entering and causing damage. This feature is especially important in the automotive and construction industries.

3. Noise Reduction:

In the automotive and construction industries, seal strips are used to reduce noise levels by sealing gaps and preventing sound from traveling through joints. This feature contributes to a quieter and more comfortable environment.

4. Protection Against Contaminants:

Seal strips provide protection against contaminants such as dust, dirt, and chemicals, especially in industrial applications. They help protect sensitive equipment and machinery from external damage, reducing maintenance costs and prolonging the lifespan of products.

5. Enhanced Durability:

Seal strips made from high-quality materials, such as EPDM, silicone, or rubber, offer excellent resistance to weathering, UV radiation, and wear and tear. This ensures that the seals last longer, reducing the need for frequent replacements and improving overall product longevity.

Choosing the Right Seal Strip

When selecting a seal strip for a specific application, several factors should be considered:

Material: The material of the seal strip plays a crucial role in its performance. Rubber, silicone, and EPDM are common choices depending on the temperature range, environmental conditions, and application type.

Size and Shape: Seal strips come in a variety of sizes and shapes. The right size and shape will depend on the gaps or joints that need to be sealed. Proper measurements are essential to ensure a tight and effective seal.

Environmental Conditions: Consider the environmental factors, such as temperature, exposure to chemicals, and weather conditions, to determine the appropriate seal strip material. For example, silicone may be more suitable for high-temperature environments, while EPDM may be preferred for outdoor use.

Durability and Resistance: Depending on the level of exposure to wear and tear, choose a seal strip that offers sufficient durability. Some seal strips are designed for heavy-duty applications, while others are better suited for lighter use.

Conclusion

Seal strips are vital components in a wide range of industries, providing essential sealing, insulation, and protection. From automotive applications to construction and electronics, seal strips help enhance energy efficiency, prevent leaks, and protect products from damage. Choosing the right seal strip material, size, and shape is crucial for optimal performance, ensuring that gaps are effectively sealed, and the desired functionality is achieved. Whether for industrial machinery, HVAC systems, or home appliances, seal strips are an indispensable part of modern life.