What Is a Horizontal V Grooving Machine and How Does It Benefit Your Manufacturing Process?

2024-11-15

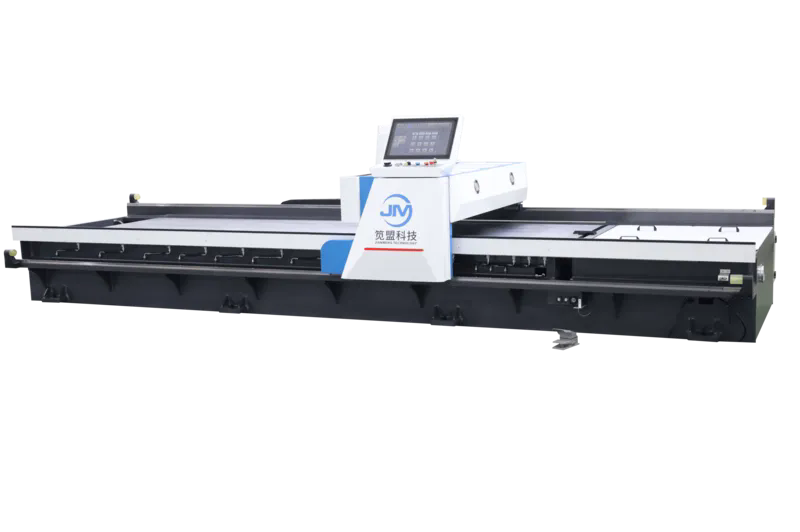

In modern manufacturing, precision and efficiency are key to staying competitive. For industries dealing with sheet metal fabrication, a Horizontal V Grooving Machine (VGM) is an indispensable tool that provides both. But what exactly is a Horizontal V Grooving Machine, and why should manufacturers consider adding one to their production line? Let's explore its features, benefits, and applications in detail.

What Is a Horizontal V Grooving Machine?

A Horizontal V Grooving Machine is a specialized tool used in sheet metal fabrication to create precise grooves along the edges of metal sheets. The grooves, typically in a "V" shape, are formed by a rotating cutter that makes a series of cuts on the surface of the metal. This type of grooving is critical for producing fold lines in the material, especially when preparing it for bending, forming, or assembling.

Unlike traditional vertical grooving machines, the horizontal design of this machine allows for smoother handling of larger sheets and provides a more consistent groove depth across the length of the material. Horizontal V grooving machines are widely used in industries where sheet metal needs to be bent or shaped with high precision, such as HVAC systems, cabinetry, and electrical enclosures.

Key Features of Horizontal V Grooving Machines

- Horizontal Cutting Mechanism: The key distinction of this machine is its horizontal cutting action, which makes it ideal for handling large and heavy sheets with minimal distortion or warping.

- Precision Grooving: The machine is designed to create highly accurate V-shaped grooves at predetermined depths and angles, ensuring that the material can be bent consistently without cracking or deforming.

- Adjustable Grooving Parameters: Operators can typically adjust groove width, depth, and angle settings based on the specific needs of the material being processed.

- High-Speed Operation: Many Horizontal V Grooving Machines are designed for high-speed operation, which allows for faster production times and greater efficiency in manufacturing.

- User-Friendly Controls: Modern VGMs often feature digital controls and automated settings for precise adjustments, making the machine easy to operate and reducing the risk of human error.

Applications of Horizontal V Grooving Machines

1. Sheet Metal Bending and Forming

The most common use of a Horizontal V Grooving Machine is in preparing sheet metal for bending. The V-shaped grooves allow for controlled bending along specific lines without compromising the integrity of the material. This is especially useful for creating sharp, accurate bends in thick metals that might otherwise crack or break under pressure.

2. HVAC Ductwork

HVAC systems often require large sheets of metal to be bent into specific shapes for ductwork. Horizontal V grooving is ideal for creating the necessary fold lines, as it ensures consistent bending without compromising the strength of the material. It also allows for quicker assembly and installation of duct sections.

3. Cabinet and Furniture Manufacturing

When manufacturing cabinets, enclosures, or other metal furniture pieces, V grooving can help ensure precise folds and joints. A Horizontal V Grooving Machine can create grooves that make it easier to join metal pieces together, ensuring structural integrity and a clean, finished appearance.

4. Electrical Enclosures

In the production of electrical enclosures, precision is crucial. Horizontal V Grooving Machines are used to prepare the metal sheets for forming complex shapes that house electrical components, providing strong, stable protection against external conditions.

5. Automotive Industry

In automotive manufacturing, V grooving is often used to create parts and components that require intricate bends. The high precision of horizontal grooving machines ensures that these parts fit together perfectly, which is essential for vehicle safety and performance.

Benefits of Using a Horizontal V Grooving Machine

1. Improved Precision

The ability to create consistent, accurate grooves is one of the biggest advantages of using a Horizontal V Grooving Machine. This precision ensures that metal parts fit together seamlessly and maintain structural integrity throughout their use.

2. Faster Production

By automating the grooving process, manufacturers can reduce the time it takes to prepare metal sheets for bending or assembling. The high-speed cutting action and digital control systems allow for faster setup times and reduced downtime between operations.

3. Cost Efficiency

While the initial investment in a Horizontal V Grooving Machine might be substantial, the long-term savings are significant. The machine reduces material waste by ensuring the precise cutting of grooves, meaning less scrap material and fewer costly mistakes. Additionally, the machine increases production rates, allowing manufacturers to take on more jobs in less time.

4. Flexibility in Design

Horizontal V Grooving Machines offer flexibility in the types of bends and folds they can create. With adjustable settings for groove depth and width, these machines can accommodate a wide range of materials and design requirements, from simple folds to more complex shapes.

5. Enhanced Durability

These machines are built for durability and designed to handle tough materials, including stainless steel, aluminum, and other metals that are commonly used in heavy-duty manufacturing. As a result, they offer a longer operational life and reduced need for maintenance.

Considerations When Purchasing a Horizontal V Grooving Machine

- Material Compatibility: Ensure the machine can handle the specific types of metals you plan to work with, especially if you're working with thick or hard materials.

- Groove Dimensions: Check that the machine can create grooves with the required depth, width, and angle for your application.

- Automation Features: Many modern Horizontal V Grooving Machines come with automated features, such as CNC controls, to further enhance precision and ease of use. These features can be particularly useful in high-volume production environments.

- Size and Capacity: Consider the size of the machine and the space available in your shop. Horizontal V Grooving Machines can vary significantly in size, so it's important to choose one that fits your operational space and can accommodate your largest workpieces.

Conclusion

A Horizontal V Grooving Machine is a valuable addition to any sheet metal fabrication shop, offering precise and efficient grooving capabilities that can improve the quality and speed of your manufacturing process. Whether you’re in the HVAC, automotive, or construction industry, this machine can help you create better products with greater accuracy, all while saving time and reducing material waste. If you're looking to elevate your production efficiency and precision, investing in a Horizontal V Grooving Machine could be a game-changer.