What Makes PCB Fabrication the Backbone of Modern Electronics?

2024-11-20

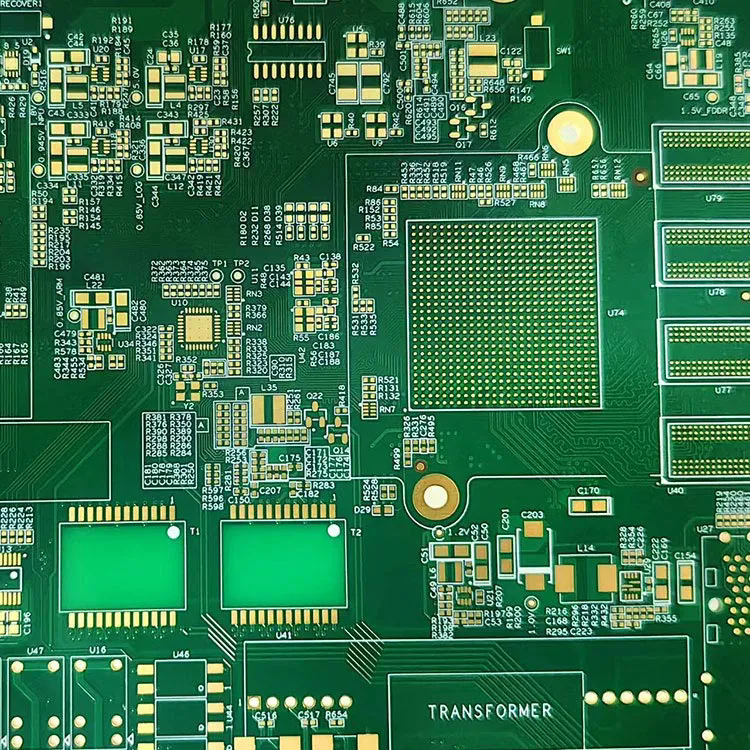

In the world of modern technology, Printed Circuit Boards (PCBs) are the silent heroes powering everything from smartphones to space shuttles. But have you ever wondered how these intricate boards come to life? PCB fabrication is the cornerstone of electronics manufacturing, transforming raw materials into the essential circuits that drive our devices. Let’s explore why this process is so critical and what it entails.

What Is PCB Fabrication?

PCB fabrication is the process of manufacturing a printed circuit board, which serves as the foundation for electronic components and connections. It involves a series of meticulous steps to create a functional board capable of transmitting electrical signals reliably.

Unlike assembly, which involves placing components onto the board, fabrication focuses on creating the physical structure of the PCB itself.

Why Is PCB Fabrication So Important?

1. Foundation of Electronics:

- Every electronic device relies on a PCB to house and interconnect its components.

2. Customization:

- PCBs are tailored to specific applications, from simple single-layer designs to complex multi-layer boards.

3. Reliability:

- Proper fabrication ensures durability and consistent performance, even in harsh environments.

Without accurate fabrication, even the best designs would fail to function effectively.

How Does PCB Fabrication Work?

The fabrication process involves several steps, each requiring precision and expertise:

1. Design Preparation:

- The process starts with a detailed design file, typically created using CAD software, which specifies the layout, layers, and electrical connections.

2. Material Selection:

- Substrates like FR4 (fiberglass epoxy) or flexible materials are chosen based on the application’s requirements.

3. Printing the Circuit Pattern:

- Using techniques like photoengraving, the circuit pattern is transferred onto the copper-clad board.

4. Etching:

- Unwanted copper is removed, leaving behind the desired circuit traces.

5. Drilling:

- Precision drilling creates holes for components and interlayer connections (vias).

6. Plating and Finishing:

- Conductive materials are added to vias, and the surface is coated for corrosion resistance and solderability.

7. Quality Control:

- Rigorous testing ensures the board meets electrical and mechanical standards before delivery.

What Challenges Arise in PCB Fabrication?

1. Miniaturization:

- As devices become smaller, fabricating PCBs with fine traces and tight tolerances becomes more complex.

2. Multi-Layer Complexity:

- Advanced designs require precise alignment of multiple layers to ensure functionality.

3. Material Compatibility:

- Selecting the right materials to balance cost, durability, and performance is a constant challenge.

4. Environmental Regulations:

- Fabrication processes must adhere to eco-friendly practices, including proper waste disposal and material recycling.

How Is Technology Advancing PCB Fabrication?

Innovations in PCB fabrication are driving the electronics industry forward:

- Laser Drilling: Enables precise and efficient hole creation for micro-vias.

- HDI Technology: High-Density Interconnect PCBs support more compact and powerful designs.

- Flexible and Rigid-Flex Boards: Open new possibilities for wearable tech and compact devices.

- Automation: Streamlines processes, reduces errors, and enhances production speed.

These advancements make PCBs more capable of supporting the complex demands of modern electronics.

What Makes a Good PCB Fabrication Partner?

Choosing the right fabrication partner is crucial for success. Look for a manufacturer who offers:

- Expertise in handling complex designs.

- High-quality materials and advanced equipment.

- Rigorous quality control processes.

- On-time delivery to meet production schedules.

Collaborating with a trusted partner ensures that your PCB is fabricated to the highest standards, setting the foundation for reliable products.

Conclusion

PCB fabrication is not just a manufacturing process—it’s the backbone of innovation in the electronics industry. From the simplest gadgets to the most sophisticated systems, every device relies on expertly fabricated PCBs to function flawlessly.

So, next time you marvel at your smartphone or a high-tech gadget, remember the intricate journey of PCB fabrication that made it all possible. Isn’t it amazing how much goes into creating the invisible framework of modern technology?